Fabric Printing

Fabric printing has its own challenges.

The same artwork considerations are present for fabric printing as for any other type of screen printing, so please check out our artwork preparation section if you need to.

The same artwork considerations are present for fabric printing as for any other type of screen printing, so please check out our artwork preparation section if you need to.

What we need from you

Placement

Direction of Print

Ink Colours

Multiple Colourways

Mock-ups and spec. sheets may seem like a lot of work but really they're not. You will already have your artwork in an editable format, so outlining a fabric piece, adding measurement details and duplicating coloursways should only take a couple of minutes.

Placement

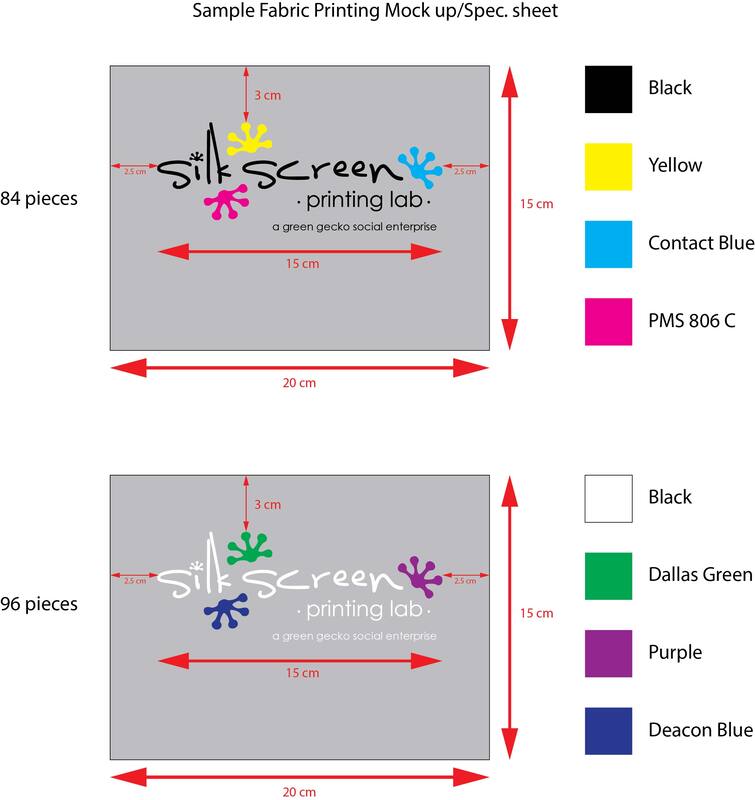

- Indicate clearly where on the fabric the print needs to go. The best way to do this is with a mock-up/spec sheet.

- Clearly mark which side of the fabric you would like us to print. This could be done with tailor's chalk, or a pinned piece of paper on each piece. Make sure it's something that won't fall off easily and make sure you communicate clearly to us how you have marked the fabric.

Direction of Print

- If your fabric has a weave that you need to be in a certain direction against the print, please indicate clearly which direction we need to print.

Ink Colours

- Clearly communicate the colours required. The best way to do this is with a mock-up/spec sheet.

Multiple Colourways

- If you need the same design printed using different inks, please make it clear how many of each you need with which inks. The best way to do this is with a mock-up/spec sheet.

Mock-ups and spec. sheets may seem like a lot of work but really they're not. You will already have your artwork in an editable format, so outlining a fabric piece, adding measurement details and duplicating coloursways should only take a couple of minutes.

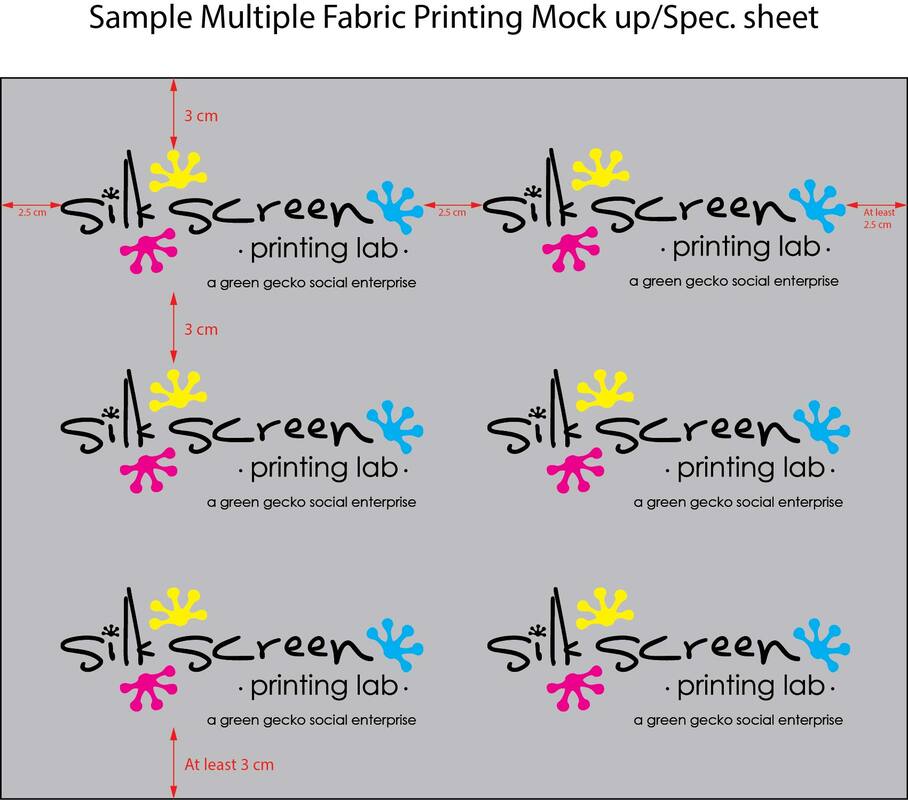

If you need multiple prints on one piece of fabric, clearly state the distance between prints and between the fabric edges. Again, a mock-up/spec. sheet is the best way to do this.

There are some types of fabric we cannot print.

Very thin fabric with a low thread count.

Highly synthetic fabrics.

Very stretchy fabrics.

Feel free to drop in and show us a sample of your fabric. That way we can do some tests and let you know if it's possible to print.

Very thin fabric with a low thread count.

- This fabric is very hard to line up straight on our printing presses.

- The ink doesnt have enough fabric to "hold on to" so will crack after curing.

- We use a light adhesive on our printing platens to hold fabric in place. Thin, delicate fabric can easily be damaged when removed from the platens.

Highly synthetic fabrics.

- These fabrics will often not adhere to the platens of our printing presses with the usual amount of adhesive. If we use more adhesive there is a danger of a sticky residue being left on the underside of the fabric after printing and curing.

- They may also have a low tolerance to heat. This could result in them warping under the heat of our heat guns and heat presses. In the worst scenario, they could catch fire.

- Dye migration often occurs with synthetic fabrics. This is when dye from polyester fabric bleeds into the ink during the curing process. An example of this is white ink that turns pink after having been printed on a red polyester t-shirt. This doesn't just apply to white ink, any mid to light ink can take on a dulled, pastel appearance. Unfortunately dye migration doesn't always occur immediately, it can take hours, even days to happen.

Very stretchy fabrics.

- These fabrics are very challenging to get straight on the platens. If they are not adhered to the platens perfectly straight, when they are removed after printing and go back into shape, the print will be warped.

Feel free to drop in and show us a sample of your fabric. That way we can do some tests and let you know if it's possible to print.